Esperanto

Esperanto

Shqiptare

Shqiptare

Euskara

Euskara

Zulu

Zulu

Latinus

Latinus

Cymraeg

Cymraeg

தமிழ்

தமிழ்

Slovak

Slovak

Slovak

Slovak

Afrikaans

Afrikaans

Categories

Contact Us

E-mail:

team3@huataogroup.com

Phone/WhatsApp:

+86-13331385676

Address:

NO.298 Zhonghua North Street,Shijiazhuang city, China.

Forming Fabric

- Product Details

-

Description

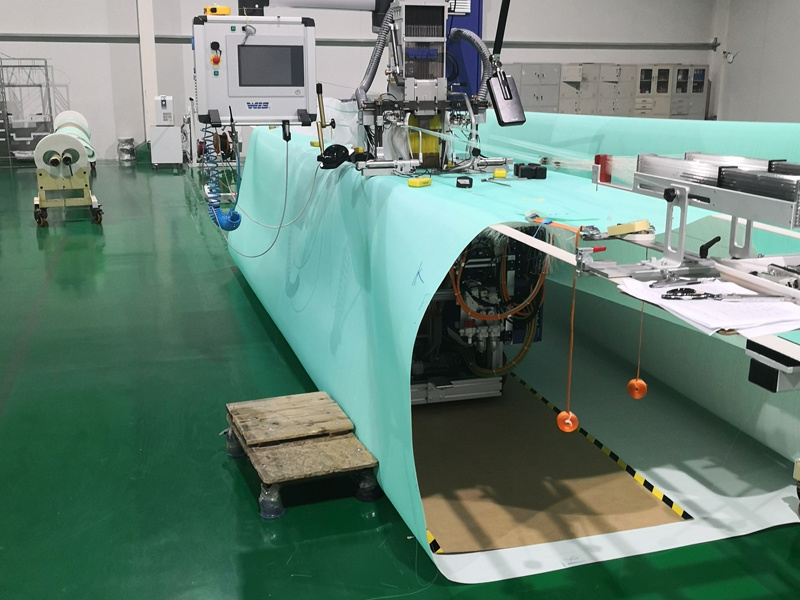

In the forming section of the paper machine, a mixture of approximately 99% water and 1% cellulose fibers and filler material is introduced uniformly across the width of the forming fabric. During this process, the forming fabric acts as both a conveyor belt and a dehydrator. When the fabric moves quickly, more than 96% of the water is drained through the special voids in the fabric, while the fibers and fillers remain on top of the fabric to form a paper sheet structure. Huatao has constantly improved their forming fabric technology and created fabrics providing excellent runnability, high wear resistance, long running time, good paper profiles and good retention.

Application Paper Machine Type

1. Fourdrinier Paper Machine

2. Twin Wire Former Paper Machine

3. Crescent Tissue Machine

4. Pulp Drying MachineFeature & Advantage

1. Excellent drainage capacity

2. Improve fiber retention

3. Long lifetime and better dimensional stability

4. Better running stability and abrasion resistance

5. Ease of maintenance

6. Professional designProduct Gallery

Key words:

Get A Quote

Note: Please leave your email address, our professionals will contact you as soon as possible!