Esperanto

Esperanto

Shqiptare

Shqiptare

Euskara

Euskara

Zulu

Zulu

Latinus

Latinus

Cymraeg

Cymraeg

தமிழ்

தமிழ்

Slovak

Slovak

Slovak

Slovak

Afrikaans

Afrikaans

Categories

Contact Us

E-mail:

team3@huataogroup.com

Phone/WhatsApp:

+86-13331385676

Address:

NO.298 Zhonghua North Street,Shijiazhuang city, China.

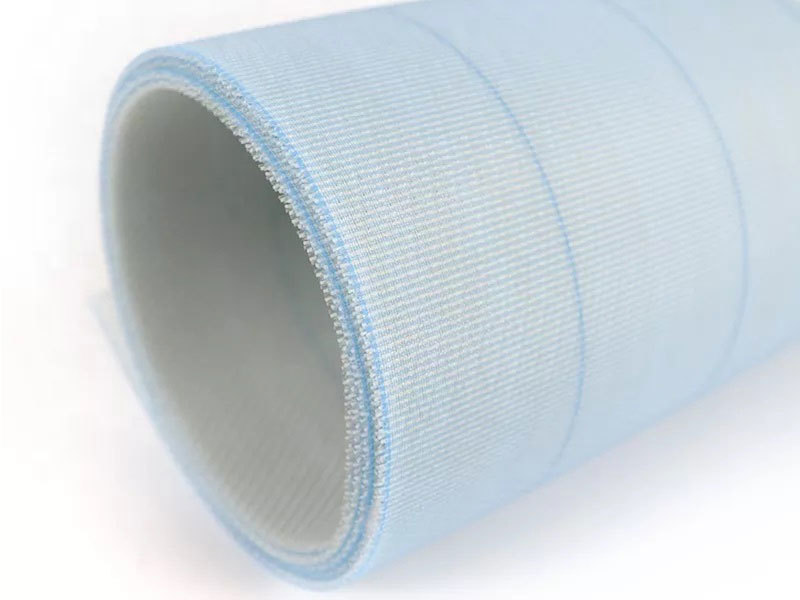

Press Felt / Paper Making Felt

- Product Details

-

Description

Press felts play an important role in removing moisture from the paper web after the forming section, while imparting smoothness and transporting it to the dryer section. To this end, press felts need to provide the following functions: water removal, smoothing and runnability.

According to the location on the paper machine can be divided into wet felts, top felt and dryer felt. The function of the wet felt is to press the raw paper to make it dehydrated and smooth the paper surface. The top felt is used above the wet felt and plays the role of leading, flattening paper and drying. Dryer felt wraps the dryer cylinder to iron and dry the paper.

Features

1. The dehydration rate of press felts is very high. High anti-compaction capacity.

2. Smooth and compact press felts surface, Extremely high elasticity, and recoverability.

3. Press felts are easy to maintain a clean structure; no stickiness, no uneven clogging.

4. The total energy consumption of press felts is low. Strong drainability and larger void volume.

5. Long holding time of wear resistance and plastic strength of felt.

6. Smooth felt surface and even pressure distribution.Feature Of Seam Press Felt

1. Easy to seam on the machine.

2. Safe, easy and quick installations decrease the need of manpower and crane time, and thereby.

3. Increase the efficiency of the shut down time.

4. Durable structure with strong and non-marking seam area.

5. Good resistance against compaction and filling.

6. Good water handling capacityProduct Gallery

Key words:

Get A Quote

Note: Please leave your email address, our professionals will contact you as soon as possible!