language

English

العربية

বাংলাদেশ

Български

Hrvatski

Česky

Dansk

Nederland

Esperanto

Esperanto

Slovenski

Filipino

Suomi

Français

Maori

Shqiptare

Shqiptare

Georgian

Euskara

Euskara

Deutsch

Ελλάδα

ישראל

इंडिया

Magyarország

Ísland

Indonesia

Irlanda

Italia

日本語

Sovensko

Հայաստան

한국

Kyrgyz

ປະເທດລາວ

Zulu

Zulu

Latvian

Lithuanian

Luxembourgish

Latinus

Latinus

Macedonian

Малайская

Maltese

Монгол улс

Cymraeg

Cymraeg

ဗမာ

தமிழ்

தமிழ்

नेपाल

Norge

ایران

Polska

Portugal

România

Российская

Србија

Slovak

Slovak

Србија

Slovak

Slovak

Bosanski

Slovenian

Беларус

España

Sverige

Точик

ประเทศไทย

Türk

Azərbaycan

Uzbek

Afrikaans

Afrikaans

Việt Nam

Contact Us

E-mail:

team3@huataogroup.com

Phone/WhatsApp:

+86-13331385676

Address:

NO.298 Zhonghua North Street,Shijiazhuang city, China.

Crusher Series

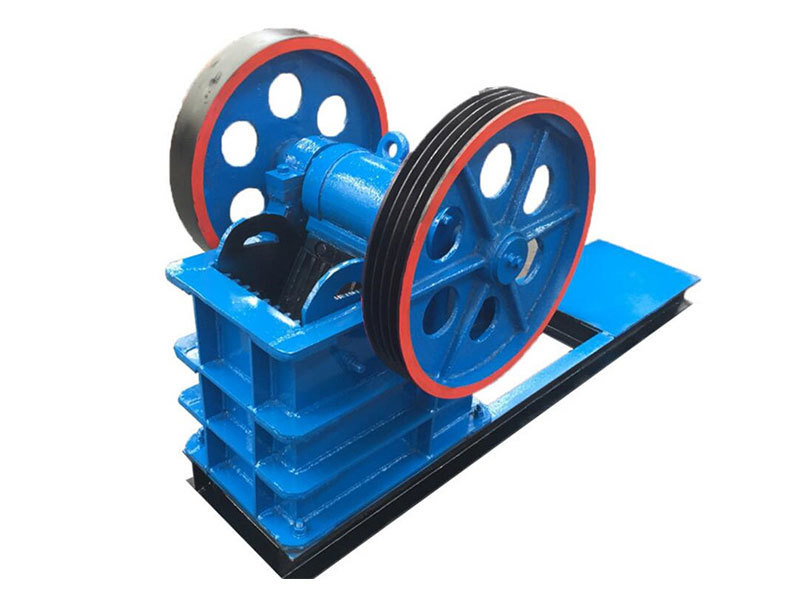

The jaw crusher consists of two jaw plates, the movable jaw and the static jaw, which form a crushing cavity. It is widely used in the crushing of various ores and bulk materials in mining and smelting, building materials, highways, railways, water conservancy and chemical industries.

Hammer crusher mainly rely on impact energy to complete the operation of crushing materials. When the hammer crusher is working, the motor drives the rotor to rotate at a high speed, and the material enters the crusher cavity evenly. The high-speed rotating hammer head rushes to the baffle plate and sieve bar in the frame, and the material larger than the sieve hole size is blocked on the sieve plate and continues to be hit and ground by the hammer until it is crushed to the required discharge particle size and finally discharged out of the machine through the sieve plate .

The motor drives high-speed rotation of rotor; materials collide with plate hammer on the rotor, and are crushed due to the high-speed impact of plate hammer; materials affected by crushing will be struck back on lining plate to crush again; finally they will be discharged from outlet. Adjustment of the clearance between back striking rack and rotor rack can change discharge size and material shape.

Cone crusher is a crushing machine suitable for raw materials in metallurgy, construction, road construction, chemical and silicate industries. According to different crushing principles and product particle size, it is divided into many models. Crusher is widely used in mining, smelting, building materials, highways, railways, water conservancy and chemical industries and many other sectors. The cone crusher has large crushing ratio, high efficiency, low energy consumption, and uniform product particle size. It is suitable for medium and fine crushing of various ores and rocks.