language

English

العربية

বাংলাদেশ

Български

Hrvatski

Česky

Dansk

Nederland

Esperanto

Esperanto

Slovenski

Filipino

Suomi

Français

Maori

Shqiptare

Shqiptare

Georgian

Euskara

Euskara

Deutsch

Ελλάδα

ישראל

इंडिया

Magyarország

Ísland

Indonesia

Irlanda

Italia

日本語

Sovensko

Հայաստան

한국

Kyrgyz

ປະເທດລາວ

Zulu

Zulu

Latvian

Lithuanian

Luxembourgish

Latinus

Latinus

Macedonian

Малайская

Maltese

Монгол улс

Cymraeg

Cymraeg

ဗမာ

தமிழ்

தமிழ்

नेपाल

Norge

ایران

Polska

Portugal

România

Российская

Србија

Slovak

Slovak

Србија

Slovak

Slovak

Bosanski

Slovenian

Беларус

España

Sverige

Точик

ประเทศไทย

Türk

Azərbaycan

Uzbek

Afrikaans

Afrikaans

Việt Nam

Categories

Contact Us

E-mail:

team3@huataogroup.com

Phone/WhatsApp:

+86-13331385676

Address:

NO.298 Zhonghua North Street,Shijiazhuang city, China.

Paper Machine Spare Parts

Chain conveyor is mainly used for conveying various kinds of pulp board, and waste paper in bulk and in bundles which can be horizontal conveyor or inclined conveyor(<30°). Intended particularly for loading of waste paper (loose or in bales) or chemical pulp into a pulper.

The air cushion headbox consists of a square taper tube device, evener roll device, top lip plate adjusting device, box body, control system, spraying device, air path system, etc. The headbox is designed with customer performance parameters, which can ensure work performance.

Can increase the sizing pressure to meet the requirements of medium and high speed paper machines.

The hydraulic headbox (hydraulic full-flow air cushion combined headbox) is suitable for paper machines with a speed of 350-1500m/min. The pulp flows from the conical stock distribution main pipe through a group of tube bundles with small diameters and step changes, and enters the Stabilizing room, there is an attenuation room above the stabilizing room.

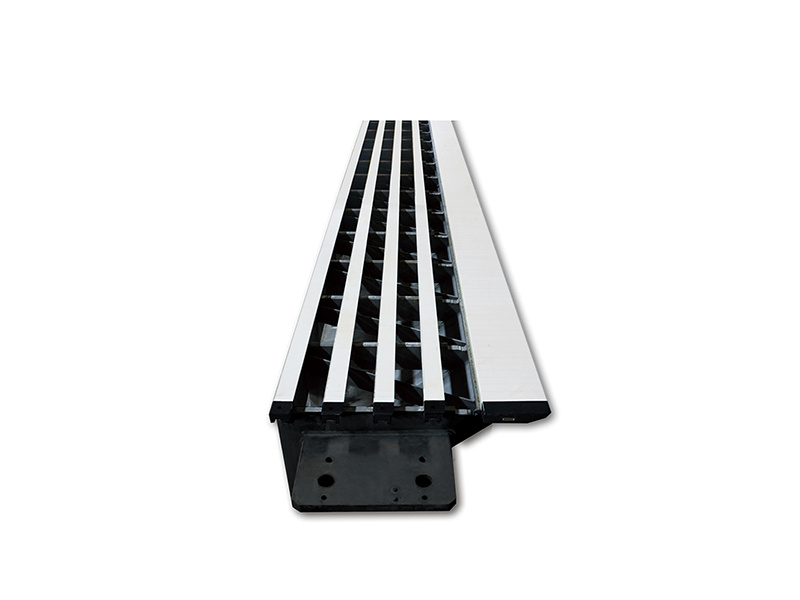

The special design structure of the forming board is that it can be installed near the breast roller, or the breast roller scraper can be installed. It can move forwards and backward and can be adjusted to the best spraying point of the slurry so that it can achieve a good sheet forming and dewatering effect. The forming board is composed of a box body and top panel.

The special design structure of the forming board is that it can be installed near the breast roller, or the breast roller scraper can be installed. It can move forwards and backward and can be adjusted to the best spraying point of the slurry so that it can achieve a good sheet forming and dewatering effect.

The forming board is composed of a box body and top panel.

This product has dense structure and high surface finish quality, with low friction coefficient and water absorption rate. It can improve the actual working time of forming wire and save energy by the most.

It has single and duo-chamber options with stable vacuum conditions. And strong reverse dewatering capability.

Tri High Vacuum Box has a reasonable structure design and is a sealed structure. It is sucked by a vacuum pump to make the paper sheet from low-pressure dehydration to high-pressure rapid dehydration, thereby speeding up the drying of the paper, enhancing the dehydration effect and forming the paper.

This felt suction box has dense structure and high surface finish quality, with low friction coefficient and water absorption rate. It can improve the actual working time of the felt and save energy by the most.

It has single and duo-chamber options with stable vacuum condition.The slot width can be adjusted to meet the requirements of different paper types and paper machine speeds.

Paper Machine Rolls are an important configuration on a paper machine, and the output stability and efficiency of the paper machine are based on the quality of the rolls and other necessary parts. Including

Cylinder Mould is used in forming section and thickener of Cylinder Mould Multi Dryer Cylinder Paper Machine. Our Cylinder mould has the characteristics of high speed, high strength, low power consumption, and long life of the wire.