Esperanto

Esperanto

Shqiptare

Shqiptare

Euskara

Euskara

Zulu

Zulu

Latinus

Latinus

Cymraeg

Cymraeg

தமிழ்

தமிழ்

Slovak

Slovak

Slovak

Slovak

Afrikaans

Afrikaans

Contact Us

E-mail:

team3@huataogroup.com

Phone/WhatsApp:

+86-13331385676

Address:

NO.298 Zhonghua North Street,Shijiazhuang city, China.

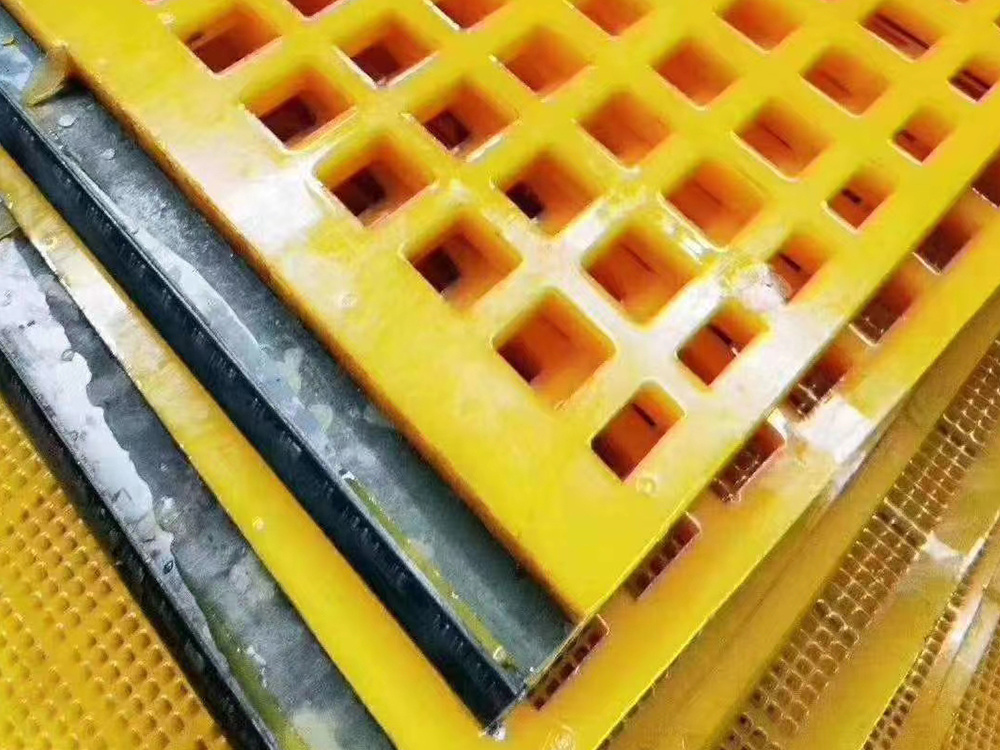

Polyurethane Fine Screen Panel

- Product Details

-

Specification

★ Material : Polyurethane

★ Type: Screen Panel

★ Aperture Range : 0.043mm - 10mm

★ eature: wear-resisting, noiseless , light etc

★ Usage : High frequency vibrating screen

★ Size : 48-30 , 1040*700mm , other size also can be designed as requests

★ Working Time : 6 months to 12 monthsDescription

★ Polyurethane Fine Screen Panel is specificialed for Derrick Stack Sizer, mainly for sieving the fine metal sands, such as: silica sands, gold sands etc.

★ The model is 48-30, 48-42, 56-42, others can be designed.

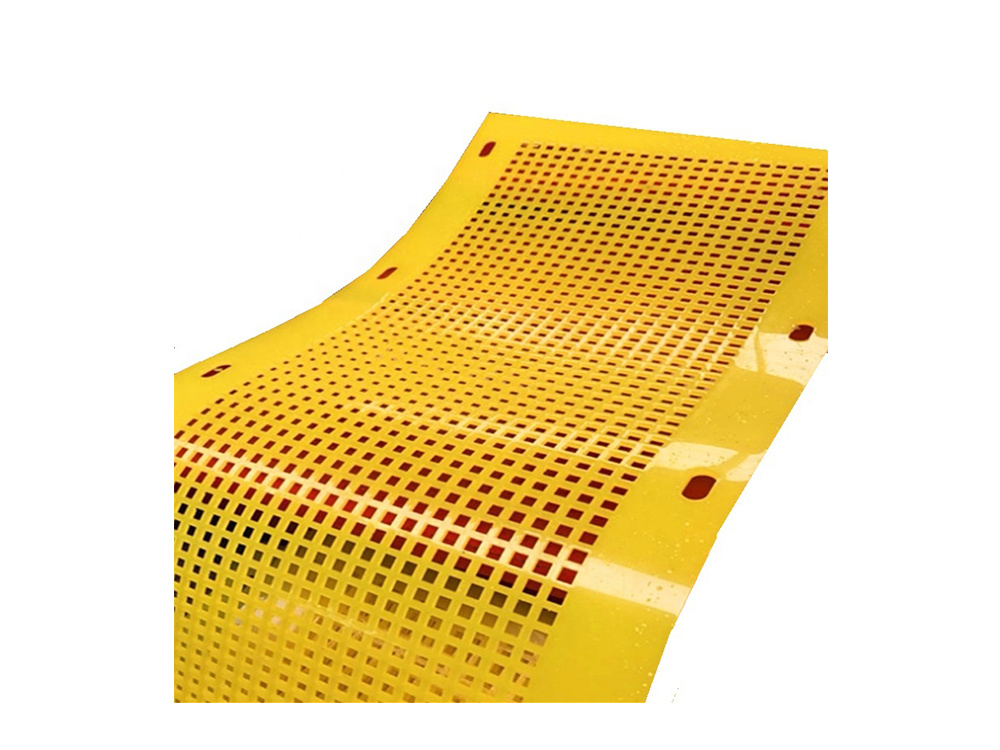

★Polyurethane Fine Screen Panel is made of polyurethane sheet with high quality screen surface. Polyurethane Fine Screen Panel is abrasion resistance and much longer service life than the woven vibrating screen mesh. Moreover, the property of anti-blinding makes it feasible to screen materials which is considered difficult or impossible to screen previously. Polyurethane Fine Screen Panel has an extremely fine openings which is as fine as 0.043mm, which is suitable for a wide variety of wet and dry applications.Features

★ Polyurethane Fine Screen Panel has extremely fine openings for accurate separation.

★ Polyurethane Fine Screen Panel with low noise and low maintenance, is the replacement products of perforated vibrating screen mesh. Additional, the Polyurethane Fine Screen Panel has higher wear resistance and acid and alkali resistance than the woven vibrating screen mesh.

★ There are hooks on the both side of polyurethane fine screen mesh, which make it easy to install the screen mesh onto vibrating screens.

★ Polyurethane Fine Screen Panel offer an extended wear life, given their flexible nature and polyurethane coating. Customers have reported between four and 10 times the life expectancy, dependent on product, regional conditions and finished product size. Not only does this extend the initial screen cost over a longer period, it also offers a substantial increase in production time available. Reducing the requirement to stop multiple times a year for change-overs has provided customers with increased capacity equating to $10,000 to $20,000 of increased finished product.

★ This is without accounting for the labour and machine hire savings.

★ Comparing the price of the screens is important, as are the potential savings and increased production time available if you don’t have to stop.

★ Due to the smooth surface of the polyurethane wire screen. The unique design and construction of the Polyurethane screen also results in lower operating noise.Advantage

★ Abrasion and wear resistance.

★ Acid and alkali resistance.

★ Fine openings for accurate separation.

★ Inlaid wedge-shape structure to strengthen the tensile strength.

★ Non-blinding.

★ Suit for almost all types of vibrating screens.

★ Lightweight and easy to install and replace.

★ Low operating and maintenance cost.

★ Low noise.

★ Long service life.Product Gallery

Key words:

Get A Quote

Note: Please leave your email address, our professionals will contact you as soon as possible!

Related Products