Esperanto

Esperanto

Shqiptare

Shqiptare

Euskara

Euskara

Zulu

Zulu

Latinus

Latinus

Cymraeg

Cymraeg

தமிழ்

தமிழ்

Slovak

Slovak

Slovak

Slovak

Afrikaans

Afrikaans

Contact Us

E-mail:

team3@huataogroup.com

Phone/WhatsApp:

+86-13331385676

Address:

NO.298 Zhonghua North Street,Shijiazhuang city, China.

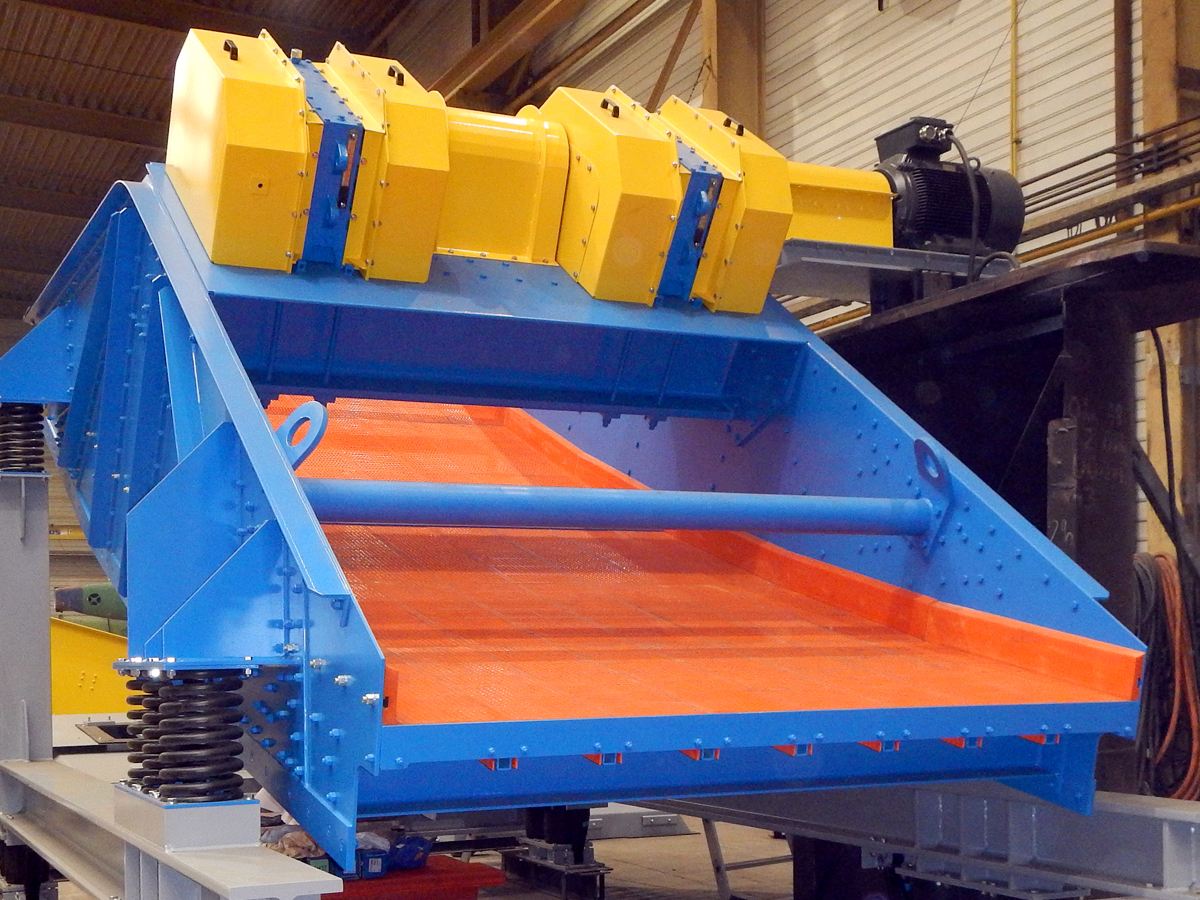

Banana Screen

- Product Details

-

Description

★ The Banana Screen is mainly used for the classification of medium and fine-grained materials with high content of fines. The banana screen surface is arranged in five or six sections with different inclination angles. Its unique structure makes it more suitable for working conditions with a large number of fine particles in the material, and the classification effect of medium and fine coal is more significant. In the coal industry, banana screen is a new application, which can replace multiple equal thickness screening systems consisting of a series of circular vibrating screens or linear screens.

Instructions

★ Banana screen is suitable for high-load screening, dehydration and de-intermediation operations with feed particle size ≤300mm and classification particle size of 0.5-100mm;

★ The screen panels can be used metal woven screen wire mesh, stainless steel slit wire mesh, polyurethane screen or polyurethane rail seat screen(WS85);

★ Giant square beam, rubber-coated protection, 610mm long feeding buffer protection, large layer spacing design is convenient for maintenance;

★ Using NJ exciter, standard FAG or SKF bearing;

★ Self-synchronization technology, gear-free maintenance, low noise and high working reliability;

★ When ordering, in addition to indicating the model and quantity, the user must also indicate the size of the sieve hole, the form of the sieve mesh and the installation angle of the sieve machine;

★ The motor can be installed on the left or right side, please specify if there are installation requirements, otherwise it will be supplied in the form of left-side installation;

★ Optional automatic lubrication device.Product Gallery

Key words:

Get A Quote

Note: Please leave your email address, our professionals will contact you as soon as possible!

Related Products

Content update in progress